Products

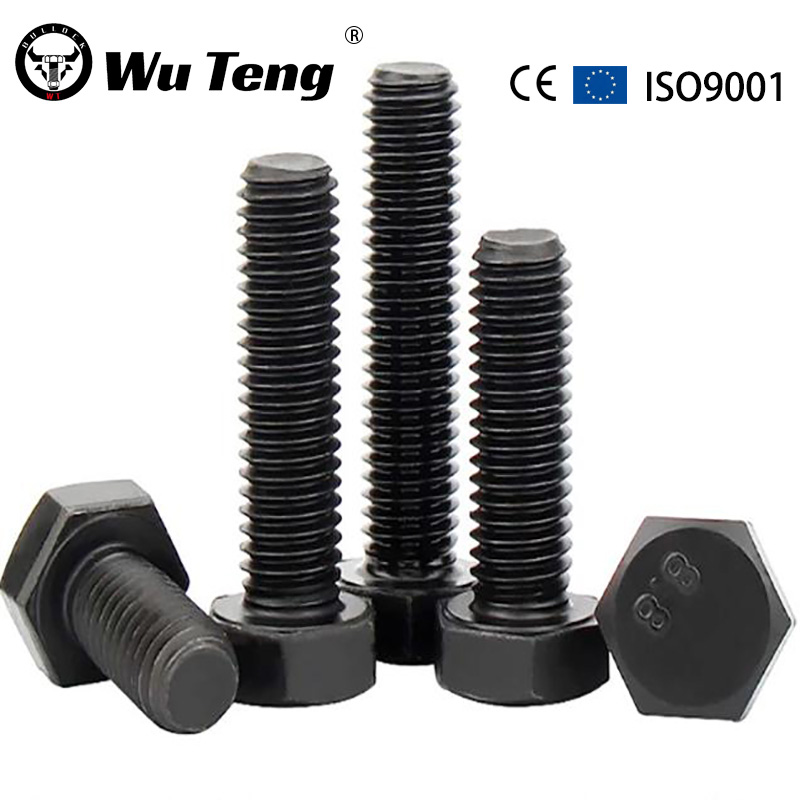

DIN931 Black Grade 8.8 10.9 12.9 Hex Bolt M48 M46 M14 1.75 10Mm 40Mm 45Mm Hex Head Bolts With Half Thread

The DIN 933 standard is applicable to fully threaded hexagonal bolts with a thread diameter of M1.6-M52, and its product grades are A and B.

The A-level regulations are: d ≤ 24mm and l ≤ 10d or l ≤ 150mm (whichever is smaller); The regulations for Class B are: d>24mm or l>10d or l>150mm (whichever is smaller). Among them, d represents the thread diameter, and l represents the bolt length. Different product grades have corresponding values for opposite edges s, diagonal e, thickness k, and length tolerance.

The general thread diameter specification of DIN 933 bolts is M3-M64, and the common carbon steel performance grades are mainly 8.8 and 10.9. When d ≤ 39mm, stainless steel is usually A2-50/A2-70/A4-70/A4-80, which can refer to ISO 3506-1 or DIN 267-11.

The bolts of this standard are generally in metric (coarse thread) and fine thread, measured in millimeters (mm). The tolerance for DIN 933 coarse thread is 6g. Common coatings on the market include black coating, electroplating (blue white zinc, yellow colored zinc), and non electrolytic zinc powder coating (GEO). The tolerance fit before coating is mainly 6g/6H, and the tolerance band fit after galvanizing can be changed to 6h/6G. However, due to the influence of surface coating thickness after coating, when testing threads with corresponding tolerance gauges, there may be situations where they cannot fit. At this time, nut installation testing with matching specifications can be carried out.

DIN 933 bolt is a fully threaded hexagonal head bolt with a wide range of applications, commonly found in the following fields:

- Mechanical manufacturing: used for the assembly and fixation of mechanical equipment, connecting various mechanical components.

- Construction engineering: such as fixing steel structures, installing brackets, connectors, etc.

- Automotive industry: can be used for fastening parts such as the engine, chassis, and body of automobiles.

- Electronic devices: They play a role in connecting and fixing in the assembly of some electronic devices.

- Petrochemical industry: suitable for the connection of chemical equipment, pipelines, etc. Some DIN 933 bolts can meet the anti-corrosion requirements of the chemical environment.

- Shipbuilding industry: used for ship construction and equipment installation.

- Aerospace: Used in areas with high requirements for strength and reliability.

- Energy field: including the installation and fixation of equipment such as wind power generation and solar energy.

- Manufacturing of pumps and valves: as connectors for pump shafts and valve stems.

- Industrial equipment: Assembly of various general industrial equipment.